Sheathing with a professional sheet of the facade of a wooden house. Sheathing the walls of the house with corrugated board

- How to choose the right material for cladding

- How to calculate the amount of corrugated board

- Facade finishing features

- Building material installation technology

- How to lay corrugated board

- Finishing the pediment of the house

Decking - universal construction material high quality, which is used in different types works. You can cover the roof with a professional sheet, clad the walls from the outside and from the inside, beautiful fences are obtained from it.

Increasingly, they began to make sheathing for the house from corrugated board. A house with corrugated boarding is comfortable, beautiful and durable. The variety of colors of building materials allows you to choose any to your taste.

Sheets of corrugated board are attached to the frame with self-tapping screws with a rubber sealing washer.

How to choose the right material for cladding

Finishing the facade using a profiled sheet is enough reliable way skins.

It will effectively protect the building in case of high humidity, under adverse weather conditions, in case of mechanical impacts.

Before starting work, it is necessary to clearly determine what the appearance of the future facade should be, perhaps to make a sketch, a preliminary plan.

Modern manufacturers of building materials offer the following options for profiled sheets:

- wall corrugated board - it is used in the decoration of walls and fences. Manufacturers designate it with the letter C;

- roofing sheeting is used for wall cladding or roofing. Such building material is indicated by the marking K;

- bearing profiled sheet is the most reliable and durable among other similar materials. It is used in the installation of floors between floors. It may be labeled H or K.

Among buyers, ceiling corrugated board is no less in demand. It is used when working in industrial premises, for sheathing the ceilings of outbuildings.

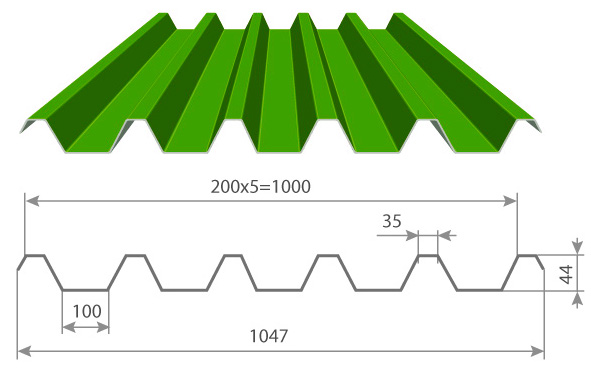

To perform wall cladding, you should choose wall corrugated board, which is marked as C8. It has a corrugation height of 8 mm, width - 1150 mm. The thickness of the profiled sheet is 0.6 mm.

In addition to such a sheet, sheets marked C21, C44 are used for sheathing. They are distinguished not only by good strength, but also by rigidity, which is very important for any facade.

Back to index

How to calculate the amount of corrugated board

Before you buy a profiled sheet, you need to calculate the amount of material needed for work. The calculation of the material for cladding the house with a profiled sheet is carried out taking into account the chosen technology of work. The area that should be covered with a profiled sheet is calculated, additional elements are taken into account - drainage, corners, window frames, and so on. The area of the facade is calculated taking into account door and window openings, it is better not to subtract them - part of the material still goes to cutting.

Back to index

Facade finishing features

Thanks to a wide variety of colors, corrugated board goes well with any architectural style of the building.

Finishing the facade using a profiled sheet has a number of features. Among them are the following:

- profiled sheet is distinguished not only by its low price, but also by ease of installation;

- long service life. With proper installation, the profiled sheet can last up to 50 years;

- good resistance to corrosion, the material is weakly influenced by undesirable weather conditions, constant humidity;

- fire safety. Finishing corrugated board refers to non-combustible materials, with high temperatures will not emit toxic substances;

- the appearance of the material is very attractive. Properly installed corrugated board will decorate even an architecturally very stylish residential building. You can use sheets of different shades, which will be installed in a checkerboard pattern or in parallel multi-colored stripes.

Working with the material is quite fast and easy. Inexpensive materials such as self-tapping screws, films and boards can be used as auxiliary materials.

Back to index

Building material installation technology

Among the features of the technology of correctly executed installation is not only ease of implementation, but also low costs, as well as a large number of design solutions.

Basically, the whole idea of installation according to all the rules is that air circulation passes between the sheet and the facade, which makes it possible to regulate the temperature, allows you to remove excess moisture, that is, we are talking about houses that turn out to be exceptionally convenient and comfortable for living.

Back to index

How to lay corrugated board

Finishing the facade using corrugated board is performed as follows:

Wall decking is often used in the construction of private houses and large industrial buildings. This type of material is used both for exterior wall decoration and interior.

- first, horizontal waterproofing is performed along the entire perimeter of the foundation. For this, it is convenient to use rolled materials; inexpensive mineral wool is perfect;

- further, a guide profile is fixed to the foundation using special anchor bolts;

- vertical racks are mounted in the guide profile, this results in a wall frame;

- then we proceed to the installation of vapor barrier, insulation material, wind protection;

- carried out in stages, the sheets are attached to the racks of the frame. This is done using self-tapping screws specially designed for this, equipped with colored heads and rubber gaskets. Such additions protect the sheets from scratches and damage.

In order to properly decorate all openings (both window and door), corners and drainage are used, which must be matched to the color of the corrugated board. Wall sheets can be arranged in different directions: vertical, horizontal, sometimes they can be arranged diagonally. You can enhance the attractiveness and expressiveness of the facade with the help of additional corner elements.

Due to the light weight of the building material, it is possible to use a profiled sheet on any frames. Self-tapping screws used for attaching profiled sheets to rails must be polymer or galvanized, with rubber gaskets. You should not save on them: reliable fastenings are the basis for the durability of the structure.

Decorating a house with corrugated board is a relatively inexpensive and effective way to design a facade. This method of wall cladding has its advantages.

Advantages of corrugated board finishing

The professional flooring is a finishing corrugated galvanized sheet. On the one hand, a polymer coating is applied to its surface, protecting it from external influences and increasing its service life. Cover color may vary.

Advantages of cladding a house with a profiled sheet:

- Good protection of the walls of the building from the weather;

- Possibility to arrange ventilated facade and thereby increase the thermal insulation of the house;

- Additional protection against noise;

- Variety of design solutions;

- Acceptable price;

- Corrosion resistance;

- Durability.

Before you buy corrugated board, you should understand its classification and features.

Material selection

For facing the walls of the building, corrugated board marked "C" (wall) is used. In addition to the letter designation, the material has a digital code, for example, 1130.0.8, where 1130 mm is the width of the profiled sheet, and 0.8 mm is the wave height. Most often it is performed with corrugated board grade C 44, C 21, C 8.

Before buying the material, you need to decide how the sheet will be located, horizontally or vertically. This depends on the choice required amount auxiliary elements:

- corner parts;

- basement ebbs;

- finishing and starting elements;

- docking profiles;

- window and door frames.

Advice: the profiled sheet is attached to the building so that there is a small gap between it and the facade for free air ventilation. So you protect the walls of the structure from the accumulation of condensate and the subsequent formation of mold and fungi.

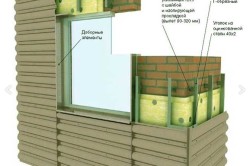

Facade from corrugated board: scheme

Plain corrugated sheeting without insulation is suitable for unheated pavilions, sheds, garages and hangars. If you have chosen this cladding for residential building, then it is recommended to make a ventilated facade. So you not only get a beautiful finish, but also increase the energy efficiency of the building.

Ventilated home decoration with corrugated board is carried out according to the following scheme:

- First, the thermal insulation of the house is made of semi-rigid mineral wool or extruded polystyrene foam.

- A layer of membrane waterproofing is attached on top of the insulation. It allows ventilation of the insulation and prevents condensation from accumulating.

- A wooden or metal frame is made for attaching profiled sheets.

- A profiled sheet is mounted on the frame.

Step-by-step instructions for decorating a house with a profiled sheet

There are two ways to finish the facade with corrugated board. They differ only in the sequence of actions:

- in the first case, insulation and waterproofing are attached to the facade of the building, and then the frame is installed on dowels into the wall and fixing the cladding;

- in the second case, the installation of the frame occurs before the fastening of the heat-insulating material.

The first method can be used if you chose as a finish extruded polystyrene foam. In the second way, it is better to make a facade of corrugated board with mineral wool insulation.

We will consider in more detail the second method of sheathing:

- With the help of dowels, a frame is attached to the walls of the house so that when laying the insulation between its surface and the skin, there is a 2.5 cm gap. The pitch of the frame rails is 50 cm. To do this, you can take galvanized guide profiles or wooden blocks that have been treated with an antiseptic.

- Next, we attach mineral wool slabs to the walls of the building. To do this, we use dish-shaped dowels. The thickness of the insulation can be 50-100 mm, depending on the region of residence and the characteristics of the walls of the house.

- On top of the mineral wool we lay a layer of membrane waterproofing film.

- Now it's the turn to fasten the casing from the profiled sheet. To do this, you need to take galvanized self-tapping screws with waterproof gaskets on top. Fastening pitch 300-400 mm. To make holes in the profiled sheet, we use a drill for metal.

- The facade of corrugated board is ready!

As you can see, cladding a house with a profiled sheet is easy to do on your own. With the help of such an inexpensive method of finishing the facade, several problems can be solved at once: to ennoble the facade and increase the thermal insulation of the house.

Profiled flooring is suitable for both roofing and facade cladding of various buildings. It is not difficult to sheathe a house with a profiled sheet, any person who once held a hammer and a hacksaw in his hands can handle it. Wall corrugated board can be used autonomously, without additional materials, but it is possible to install it with insulation, with wind protection. Sheathing a house with corrugated board is inexpensive. This is a cheap but very practical building material. The profiled facade does not fade in the sun, has a high level of mechanical strength, and is easy to install. It can also be easily dismantled if necessary. With its installation, heat losses are reduced, which is very important in the conditions of a constant rise in the cost of energy carriers.

However, the profiled sheet for facades has some disadvantages: under the influence of direct sunlight it heats up very much, you can get burned. During heavy rain and gale-force winds, when in contact with the surface of the coating, raindrops and objects carried by the wind make unpleasant sounds that reach the room. But these phenomena are rare in nature, so the positive qualities of the material are more significant than the negative ones.

How to sheathe a house with corrugated board so that it is as functional as possible? This question is not of interest  only consumers, but also professionals. Therefore, developers tirelessly improve both the technology and the materials themselves. A ventilated facade made of profiled sheet will provide a durable coating service. It will exclude the accumulation of condensate or the penetration of moisture in other ways. Even if some of the moisture gets in, the ventilation will make it possible to dry it. There is no dampness, no putrefactive accumulations - and this is one of the main conditions for the long-term functioning of not only the coating, but the entire structure.

only consumers, but also professionals. Therefore, developers tirelessly improve both the technology and the materials themselves. A ventilated facade made of profiled sheet will provide a durable coating service. It will exclude the accumulation of condensate or the penetration of moisture in other ways. Even if some of the moisture gets in, the ventilation will make it possible to dry it. There is no dampness, no putrefactive accumulations - and this is one of the main conditions for the long-term functioning of not only the coating, but the entire structure.

For facade cladding with corrugated board, steel profiles (purlins), brackets for installing girders, self-tapping screws of various lengths, anchors, paronite gaskets, basement ebb, slope strips, corner are required.

The crate is fastened under the profiled sheet with special self-tapping screws, popularly called self-tapping screws. Screws are different from ordinary self-tapping screws. Firstly, they have a hex head with a press washer, secondly, there is a metal washer with a neoprene rubber gasket, and thirdly, there is a drill tip. It requires a screwdriver with special nozzles. You can tighten such fasteners with a key.

Material calculation

To get to work, you need to calculate the amount of material for mounting the facade of corrugated board. When calculating, it is necessary to keep in mind the installation of overlapping sheets, so you need to take it with a margin. The calculation is carried out as follows: measure the height of the wall and length, calculate the area according to the school formula:

Where "a" is the length of the wall, "b" is the height of the wall. In a similar way, the area of \u200b\u200bone more wall is calculated, which is connected by a common angle with the wall on which the calculations were only made. We find the sum of the two areas obtained and multiply by 2, because the opposite walls have the same area. It remains to calculate the area of windows and doors using the same formula and subtract the resulting amount from the total area.

When sheathing the facade with a profiled sheet, the pediment is quite often covered with a different color, so it is better to consider its area separately. So, the formula for calculating the area of a triangle is:

Where "b" is the base (width) of the pediment, "h" is the height of the pediment, 1/2 is half of the entire area. But if the coating is taken on 2 pediments, then the fraction should not be multiplied. That is, you have a rectangle, because if you add 2 triangles (2 pediments), we get a rectangle.

Add 10%, and for inexperienced, it is better - 15% for stock. In order for the purchase to be economical, you need to calculate what area the profiled sheet you have chosen has. So you can calculate how many sheets you will need.

Add 10%, and for inexperienced, it is better - 15% for stock. In order for the purchase to be economical, you need to calculate what area the profiled sheet you have chosen has. So you can calculate how many sheets you will need.

Determine the number of profiles, brackets, additional elements for windows and doors.

You should choose a color, because the facade decoration with a profiled sheet also has an aesthetic function. Coatings for natural building materials are available for sale, for example, facade corrugated board under a log. The color scale is so various that it is possible to please the most whimsical buyer.

Characteristics of corrugated board and its types

This is a galvanized or polymer-coated steel sheet, it can be wavy or corrugated. Sheet thickness from 0.4 mm to one millimeter. There are several types:

- Wall (C8, C10, C18, C21, C35, C44)

- Carrier (H57, H60, H75)

- Universal (HC35, HC44).

The number next to the grade of the profiled sheet indicates the height of the corrugation or wave. The ribbed or wavy surface of the sheet is the characteristics of the aesthetic plan, but their height, width is specifications. And the bigger they are, the stronger. The sheet comes in different sizes, you can purchase a sheet that matches the height of the wall, you can choose the width. They do not need to be sawn, which is important.

You can set the waves horizontally, you can vertically. If you combine sheets along the corrugation, you can get an interesting cladding of the house with corrugated board. Often the pediment is laid with corrugations horizontally, and at home with a profiled sheet - vertically, sometimes vice versa.

You can set the waves horizontally, you can vertically. If you combine sheets along the corrugation, you can get an interesting cladding of the house with corrugated board. Often the pediment is laid with corrugations horizontally, and at home with a profiled sheet - vertically, sometimes vice versa.

Choosing a corrugated board for the facade should be based on the size of the structure. If this is an ordinary medium-sized house, then you should dwell on the average characteristics of the sheet. Popular thickness for walls is from 0.4mm to 0.7mm. It is a lightweight, easy-to-use material. A grinder with a disc (grinder) will easily cut off a piece of any shape. However, it destroys the integrity of the anti-corrosion coating at the cut points. If moisture gets in, rust will begin here and slowly spread without fail. But if such cut points can be installed in an absolutely dry place, rust will not eat it. There is another trick that can warn against rust: or drying oil. Thus, the laid corrugated board with your own hands will serve not only you, but also children. Experts advise using scissors for metal. Or use low speed saws. A manual hacksaw for metal will not let you down, although you will have to work for a long time.

Then prepare the rest of the tools and you can proceed with the installation. Laying corrugated board with your own hands means significantly saving the family budget.

Laying order

The frame or crate can be made of wood or metal. If a wooden one is mounted, then it should be impregnated with an antiseptic. If the crate is installed on wooden house, then you can get by with nails. In order for the installation of the crate under the corrugated board to turn out to be correct, you should carefully measure the walls and mark up, mark the places for attaching the brackets for the runs. Accurate marking is necessary, then the insulation plates will stand end-to-end, a high-quality heat holder is formed.

Drill holes with a drill and install brackets using gaskets and anchors. Hang on them the supporting U-shaped profiles of the crate and fasten with self-tapping screws. The profile for corrugated board is laid on the bracket with the open side up so that the insulation boards can be inserted into the groove. Fasten with screws. Fill with insulation boards, fix them with dish-shaped dowels. Use 5-6 pieces per square meter. Provide a tie-up of the joints of the insulation boards.

Drill holes with a drill and install brackets using gaskets and anchors. Hang on them the supporting U-shaped profiles of the crate and fasten with self-tapping screws. The profile for corrugated board is laid on the bracket with the open side up so that the insulation boards can be inserted into the groove. Fasten with screws. Fill with insulation boards, fix them with dish-shaped dowels. Use 5-6 pieces per square meter. Provide a tie-up of the joints of the insulation boards.

The waterproofing film will protect against the penetration of moisture into the layers of insulation, it is attached to the crate under the profiled sheet with self-tapping screws.

The wind protection fabric is laid with an overlap of 10 - 15 cm and fastened with self-tapping screws to the frame. The installation technology is many times easier, where there is an overlap width marking on the wind barrier panel. This will eliminate the beveling of the fabric.

On the entire bottom of the building, fix the basement ebb with self-tapping screws, it contributes to drainage.

Processing of window and door openings

Facing the facade of the house with a profiled sheet requires special care when finishing the openings of windows and doors. The material should be carefully measured and prepared. First of all, it is necessary to install the starting slope bar, then fix them with self-tapping screws, then install the facade profiled sheet on all sides of the opening, install the fasteners. Prepare and cut the slope strips and put them in the starting strip. Attach the sloping frames with self-tapping screws. will give your building an aesthetically flawless look.

Facing the facade of the house with a profiled sheet requires special care when finishing the openings of windows and doors. The material should be carefully measured and prepared. First of all, it is necessary to install the starting slope bar, then fix them with self-tapping screws, then install the facade profiled sheet on all sides of the opening, install the fasteners. Prepare and cut the slope strips and put them in the starting strip. Attach the sloping frames with self-tapping screws. will give your building an aesthetically flawless look.

When installing a facade profiled sheet, fastening with self-tapping screws is carried out in the lower part of the corrugation or wave. Between fasteners step - 30 cm.

Processing the pediment requires proper preparation. Here you need to develop your project. Draw a scheme of the pediment on a scale, distribute the flooring sheets on a scale, take into account the overlap and technological indents from the edge of the pediment. from a well-installed profiled sheet will not only be beautiful, but will extend the life of the entire structure for many years.

Hello everyone, first blog news, the competition ends tomorrow, you still have the opportunity to send a competitive work and play for a cash prize fund of 2000 rubles.

In the article facade decoration with a metal profiled sheet, consider the installation technology, the materials used, the pros and cons of such a finish ..

The appearance of the building is its face and the main pride of many owners. The first impression of the house is formed by the appearance of the facade. There are many ways to finish the facade:

- , the most popular way;

- , "fur coat", marble chips;

- facing, traditional way;

- , inexpensive type of finish;

- painting of the plastered facade;

- stucco, mosaic is an individual way, the desire to stand out;

- ventilated facade, which we will talk about.

What is a ventilated facade? The hinged ventilated facade consists of facing materials, insulation, which are mounted on a steel frame mounted on the wall.

Facing materials are mounted with a gap between the insulation, through which air circulates freely. The air layer removes condensate and moisture inside the facade. The outer cladding protects against sunlight, rain, wind.

This increases the life of the insulation and the preservation of its thermal properties, as it is in good humidity conditions.

This is one of the advantages of a ventilated facade, also due to the increase in sound insulation of the house, it does not allow the building to heat up in hot sunny weather.

On the modern construction market there is a large selection of facing materials and you can give your cottage a unique architectural look.

The advantages also include changing and repairing the appearance of the building by replacing external elements, a ventilated facade.

The disadvantage of a ventilated facade is the high price of some finishing materials, the flammability of the elements of the system (facade films, membranes, or plastic cladding).

- Adjustable bracket attached to the wall with dowels

- Galvanized corner, which is mounted to the bracket with rivets.

After the frame is mounted, the insulation is fixed in our case, these are mineral wool boards in two layers 20 centimeters thick. The thickness of the insulation depends on the climatic region in which the building is located.

Holes are made in the insulation plates and mounted on brackets, additionally fixed with plastic dowels to the wall of the building.

Next, the insulation is covered with a windproof waterproofing vapor-permeable membrane (film) to prevent air from blowing out of the insulation. In addition, the waterproofing membrane has the property of allowing moisture to pass through only on one side.

Due to this, it does not condense from the walls of the building on the inside and does not allow the insulation to get wet.

And the penultimate part of the facade decoration is the installation of a metal profiled sheet. As mentioned above, ceramic granite slabs, plastic siding, metal cassettes, metal siding are mounted with a gap between the insulation, and not tightly.

The gap must be at least 40 millimeters, this allows the flow of ascending air to circulate between the facing material and the insulation. Hence the name ventilated facade.

In conclusion, they frame windows, doors with flashings, window sills.

Stages of finishing the facade with a metal profile

All construction work begins with preparation. Before finishing the facade, it is necessary to purchase a tool, prepare a place for storing materials, complete and install scaffolding, or agree on an aerial platform. When working at height, protect the area dangerous for people below.

Organizational and preparatory activities are carried out in accordance with 3.01.01-85 "Organization of construction production". When working at height, in order to prevent accidents, it is necessary to get acquainted with the rules of SNiP 3.03.01-87 "Bearing and enclosing structures" and safety regulations SNiP III-4-80.

Tools used in facade finishing work:

- Lace;

- Level;

- Roulette;

- Plumb;

- Building level;

- Construction pencils or marker;

- Perforator with a drill for concrete;

- A hammer;

- Riveter;

- Bulgarian for metal.

Marking for brackets

Facade work begins with marking the support brackets on the wall of the house. Lighthouse vertical and horizontal extreme lines are outlined.

The extreme points from which we will measure the distance are set under the brackets using. From these points, using a tape measure, all intermediate points for mounting the brackets are measured and marked with a marker.

With the help of a plumb line lowered from the roof of the building, we determine the vertical lines. With the help of an aerial platform or construction scaffolds, the places for mounting the brackets vertically are marked.

Brackets are marked and installed under the profiled sheet with a distance of 1 meter horizontally and 1 meter vertically.

Mounting brackets

After everything has been marked out, we make a hole in the wall using a perforator and a concrete drill with a diameter depending on the size of the anchor dowel.

Paronite gaskets

Before fixing the bracket to the wall, install the paronite gasket.

Using anchor dowels, we mount the bearing brackets.

Ventilation subsystem.

The next operation is the laying of insulation and wind protection. Mounted on brackets as described above. Insulation installation starts from the bottom up.

I install the insulation plates in a checkerboard pattern so that there is not one continuous joint for the entire length of the wall.

With a two-layer installation of insulation, the top sheet should cover the joints of the lower plates. Insulation plates are cut, they cannot be broken.

The wind and hydroprotective membrane is hung with an overlap of 100 mm. The membrane is fixed with dish-shaped dowels, by drilling a hole in the wall with a puncher through the insulation and the membrane.

Installation of guides.

Fasten the frame vertically to the adjusting brackets with rivets. We set the bracket with a fixed guide according to the building level. After installing the vertical corners, install the horizontal guides.

- Features of finishing facades with corrugated board

- Insulated facade cladding

- Pros and cons of using corrugated board for facade decoration

Decking is one of the best materials for facade cladding. It allows you to create a ventilated skin and for a long time retains its strength and attractive appearance. This is provided modern technology production of profiled sheets, which involves the application of a zinc coating on a metal base, followed by the application of a polymer layer.

Facing the facade with a profiled sheet can be used both for residential buildings and for administrative buildings. allows you to give the building an original appearance. In addition, this material is quite economical, its use will not entail large costs.

Sheathing of the house can be carried out vertically or horizontally.

The principle of mounting the profiled sheet in this case will be the same, the difference will be only in the direction of the intermediary strips. This facade cladding allows you to give it an individual and unique look. The corrugated board has a low weight, which allows it to be used on lightweight structures and greatly facilitates installation.

Features of finishing facades with corrugated board

Sheathing with steam foil is carried out on a special substructure, which includes a metal frame. The frame must be fixed to the wall, for this, mounting brackets with a projection of 9 cm to 32 cm are used, guides with different hat shapes may also be required.

Facing with a professional sheet is carried out in several stages:

- Installation of an industrial scaffold (it must be installed along all surfaces to be finished). Stretching the protective mesh from the outside.

- Fastening hangers to the wall with dowels. The step between pairs of suspensions should be 50 cm.

- Installation of insulation (it is recommended to mount it in 2 layers).

- Installation of a heat-insulating layer, which will protect the insulation from moisture.

- Fixing guide profiles with self-tapping screws to hangers.

- Installation of profiled sheets with self-tapping screws and rivets.

- Sheathing corners and slopes.

Finishing the facade of the house involves the use of wall corrugated board PS-18, PS-10 or PS-20. These types of material do not have capillary grooves, making interchangeability easier various parts sheet. For fastening, self-tapping screws 4.8x38 mm are used, which are screwed into the wave of the sheet. For installation, you will need an electric drill equipped with a ratchet clutch.

Back to index

Insulated facade cladding

For an insulated facade, both general basic installation rules and special specific ones apply. You need to additionally stock up on intermediary corners that will allow you to level the surface of the house for fixing the Z-profile, which allows you to fill the resulting space with insulation. The professional sheets themselves are attached to the Z-profile. This allows you to create a space through which air can circulate.