Houses from sip panels Canadian technology. Reviews of owners about houses from sip panels

All the pros and cons of SIP

“Now you can’t trust anyone. Even to yourself. I can". (from the film "17 Moments of Spring")

Hello dear readers!

Remember the Hollywood movies, when strong men tear down the walls of cottages and office buildings with their bodies, heads and fists? These walls are built from SIP - panels. On the one hand, it seems like “flimsy” structures, and on the other hand, more than half of private houses in the USA and Canada are being built using this technology and have been serving for several decades. Today's topic is a house made of SIP panels: the pros and cons.

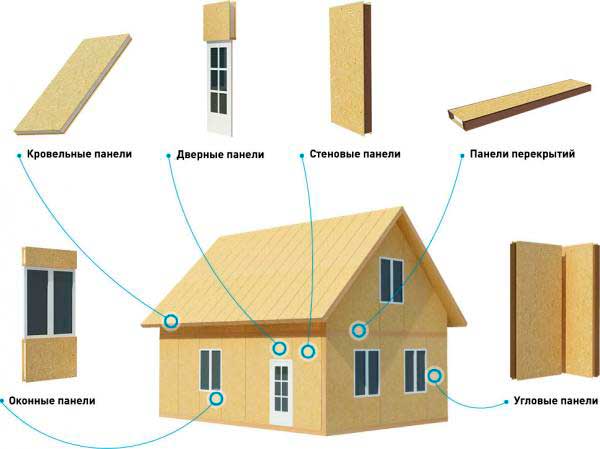

SIP - in the original - SIP ( S structural I nsulated P anel), which means - FROM structurally And isolated P anel. vernacular name in Russia - "house on Canadian technology". However, it is not entirely correct. The so-called Canadian ones are frame houses, and SIPs are panel houses, that is, they are assembled from ready-made panels produced in the factory. However, there are construction options when frame structures are sheathed with SIPs. Then we get a hybrid in the form of a frame-panel structure.

What are they from: Classical structure - three layers. Outside, an OSB sheet impregnated with "what is needed." Inside there is a dense insulation (in most cases, expanded polystyrene). In general, sandwich panels. Let's explore further...

- Strength. The panels are fastened in a tongue-and-groove manner. For connection, a bar is used (thickness from 80 mm). Composite inserts. After assembly, a reliable structure is obtained that can withstand a hurricane wind of up to 200 km / h and an earthquake of up to 8 points. The walls hold a vertical load of up to 10 tons, and a transverse load of up to 2 tons per 1 m².

“Well, foreigners are practical people and would not build such prefabricated houses in areas prone to typhoons, hurricanes and earthquakes. So? Although the point strength (pressure per 1 cm²) at the brick wall is higher, therefore, during hostilities, it will be better against bullets and shrapnel. Joke, with some truth! .. "

After a hurricane, a SIP house costs

After a hurricane, a SIP house costs

A photo: Consequences of a tornado (Georgia, USA). Uprooted fallen trees that fell on the house. But a house built from SIP is worth it. Gears are real. 32 kg x 3 = 96 kg. Earnestly?

- Ease. The average weight of a panel house with an area of 150-200 m² will be less than 15 tons. On average, the weight of 1 m² of the assembled house does not exceed 20 kg. For such a load, you can make a lightweight foundation, which means that its cost will be less. A practical option is . Professionals can install it in 1 day.

- Construction speed. A set of numbered ready-to-assemble panels and a working instruction type drawing (understandable by a person with technical education). Panels, tightly pressed at the factory, do not have air gaps and do not require additional vapor, hydro and wind insulation. This means less work, less money spent, less marriage, but more reliability. In the walls of SIP there is no moisture and shrinkage of the insulation. Well, you know how it happens when the insulation gradually slips and then the “empty” areas inside the plates freeze through.

Home construction

Panels are installed manually. A team of three hard-working, low-drinking men is able to assemble a medium-sized “box” in two weeks. By the way, you can build all year round, although the classic foundation must be “driven out” before the cold weather. Turnkey installation firms promise to do EVERYTHING in 3-4 months. So, who is looking for such a company in Moscow and the region, or just wants to know all the prices for materials and work, welcome here.

- Thermal comfort. Here the advantages are incomparable. Just numbers: the thermal conductivity of SIP 167mm thick (“classic size”) is equivalent to brickwork 2.4 meters thick. Roughly speaking, 1 cm of SIP is 15 times more heat efficient than 1 cm of brick. This is not a comparison, this is a sentence.

The resulting conclusion is energy saving. Statistics say that the cost of heating a house from SIP is 5 times less than a brick one. It's hard to argue with statistics, so it's worth considering ...

“By the way, quite a rational choice. They build and warm up quickly. The heat is kept for a long time (although less log). However, in the steam room, additional heat and vapor insulation will be required in order to prevent excessive overheating of the insulation (polystyrene foam). The only condition is that the quality of the purchased building materials must meet all the requirements of SNIPs.

SIP bath project

SIP bath project  Building a small bathroom

Building a small bathroom

A photo: Typical design of the bath. SIP - technologies (S = 28 m²). Construction of a small bath from SIP panels.

"Two in one" - environmental friendliness and durability . Environmental friendliness . It is built according to the standards of Green Building technology. This fact alone speaks of the strict control of environmental safety in the manufacture and operation. I’ll make a reservation right away, opponents question the environmental friendliness of SIP.

- Durability. Average term service, declared by European and North American manufacturers - 80 years. Quite a serious figure, designed for 2-3 generations. But this is subject to regular ongoing care (I think everyone understands this).

- Price. But here, as they say - with what to compare? However, a house made of SIP is definitely cheaper than a similar one made of brick, foam concrete and some other building materials.

Natural disadvantages of SIP

- Flammability. However, there is a point - ignition almost always occurs from the inside. And what will remain after the fire of a house built from SIP - the foundation and ash. And after the burnt brick house - the foundation and charred walls. So, in 90% of cases, burnt brick walls lose their strength by more than half and are unsuitable for further restoration. The usual recommendation of professional builders is to demolish and build everything. new house on a preserved foundation. On the basis of which the conclusion is that the consequences of a fire do not give great advantages to brick buildings.

In addition, the plates of all well-known world manufacturers have an effective impregnation that slows down the ignition process, and the insulation in the form of expanded polystyrene generally belongs to the class of self-extinguishing materials (SE class according to the international classification). Do not set it on fire with matches or a cigarette butt. Only with an open flame, although here's a video for you ...

- Environmental friendliness. The issue is quite controversial. Again, what are the disadvantages and with what to compare. I don’t want to go deep, but I will say this: if such houses are built in developed countries, then this issue is being studied. Although there are manufacturers of "third countries" supplying the markets of the same countries, it is not clear what. By the way, many food additives used by domestic cooks have long been strictly prohibited in developed countries. Well, this is so, to the development of thought ...

- "Two in one" Soundproofing and ventilation.Soundproofing . non-critical moment. According to the residents, the noise level is at the level of a panel high-rise building. Sound insulation can be improved by using drywall for interior decoration. And besides, in a private house there are no “bottom-top-side” neighbors. Therefore, the main problem is street noise.

- Ventilation . Given the sufficiently reliable tightness, the ventilation system is appropriate. Of course, you can get by with ventilation, but in winter it is uncomfortable. However, there are budget options such as mortise wall ventilation or window slotted valves. They are also put in order to. Practice shows that they are quite enough (excluding, of course, kitchens and bathrooms that require forced air exchange);

- Rodents. There are more assumptions than facts here. The insulation has a special impregnation against small nibblers. Yes, they gnaw at ordinary polystyrene, but high-quality PBS, no. Although I could be wrong. Different manufacturers - different levels of protection and quality.

And one more thing, about the myth: "Houses from SIP, for poor people":

Solid house from SIP

Solid house from SIP  Another cottage of this type

Another cottage of this type

conclusions

In terms of consumer qualities, SIP is the most effective material for an energy-saving building. And the ability to build a house on your own (of course not all) and in a short time, eliminates another part of the competitors.

That's all for now. Hope the article was helpful. Although, maybe he didn’t say much ... Subscribe to the news and recommend the blog to your friends. Further it will be more interesting...

Anecdote on the topic: “The apartment of the intellectual is being renovated. The owner drives a nail into the wall with a hat, but he does not climb.His friend, also a scientist, says thoughtfully:

“Colleague, you took a nail from the opposite wall.”

Good luck to all of you and a peaceful bright sky! Bye! Bye!

Wisdom Quote: They don’t argue about tastes: because of tastes, they scold, quarrel and swear.

Ready-made, frame technologies for building houses have entered our lives. Increasingly, there is information about SIP panels, with the help of this material you can quickly, inexpensively build a house. Product advertising praises the simplicity, reliability of construction from Greenboard SIP panels. But is it worth believing advertising slogans? How good is this material? It is worth considering in more detail.

What are SIP panels

Universal material used in construction frame houses. SIP is a structural insulating panel that has two top layers of OSB and a layer in the form of insulation. When gluing the interlayer and sheets, polyurethane glue is used. Gluing takes place under high pressure, the impact on the plate is equal to 18 tons.

OSB - oriented strand board, consisting of chips glued together in several layers using resins. This material is new, it is durable, elastic and replaces the chipboard we are used to. Manufacturers claim it is environmentally friendly. Insulation in SIP panels is plastic, foamed with high pressure, known as Styrofoam. The material is used as a heater in the arrangement of ventilated facades in construction, and has a low thermal conductivity.

OSB - oriented strand board, consisting of chips glued together in several layers using resins. This material is new, it is durable, elastic and replaces the chipboard we are used to. Manufacturers claim it is environmentally friendly. Insulation in SIP panels is plastic, foamed with high pressure, known as Styrofoam. The material is used as a heater in the arrangement of ventilated facades in construction, and has a low thermal conductivity.

She came to us not so long ago - several decades ago, all this time there are disputes about how expedient it is to build such structures in our harsh climate. People do not trust the fragile-looking material and believe that it is more profitable to build a house from brick in terms of heat retention and service life. But, nevertheless, there is no such material on the market that allows you to build a house in the shortest possible time and at the lowest cost.

Reviews of those who live in houses from SIP panels

Of course, it is not possible to determine exactly how this technology of building houses is acceptable in our climate. You can draw conclusions by reading real reviews about the technology of those people living in prefabricated houses from SIP panels. It is necessary to analyze everything that is written on the forums. And opinions are divided.

Positive reviews:

1. The house is warm

One of the forum participants, a resident of the Moscow region, talks about a number of advantages of this technology. It is worth noting that in a few years he built three houses. Before the prefabricated house from SIP panels, he erected a building from bricks and foam blocks - then only SIP panels he is so delighted with.

“The house turned out to be very warm, even in cold weather, the child runs around the house barefoot. Although they were afraid that the floor would be cold and it would definitely freeze in the corners. Nothing like that, everything is fine, I even took an infrared thermometer from a friend, measured it, the temperature is the same everywhere. They also said that there would be mice - I had not seen a single one in two years. The company built this house for me in 3 weeks.”

2. Fast and not expensive

Another person who lives in the Krasnoyarsk region, with its harsh climate, and built a house using this technology, speaks positively about the thermal insulation of his building, considering it a plus. And the climate there is quite severe.

This is my first build. I doubted for a very long time, I chose, the key point, of course, was the price, but in fact it turned out to be a comfortable and warm house. Firstly, everything is smooth, there were no problems with the finish. Second, fast. The walls were erected from a panel of 160 mm, partitions 110 mm.

3. Easy to use material and great results

The foreman writes on the forum, whose team erected a house from SIP panels for the first time.

We were hired to build a dwelling from SIP panels, before that we only built houses on a frame. But here everything is much simpler. Panels are installed evenly - no misalignment tolerances. They used standard fasteners, although they doubted that they would hold, but in practice everything is holding up perfectly. Fulfilled the order quickly - the panels are light. They tried to set fire to a piece of material, it was interesting, it’s worth saying, no matter how hard they tried - it doesn’t burn! Smoke comes out while you hold the burner, but as soon as the open fire was removed, it immediately died out.

Based on the above, we can highlight the main advantages of SIP panels:

- good thermal insulation;

- the geometry is correct;

- the material is not combustible;

- light;

- easy to work;

- not expensive.

Negative Feedback

Not a single material has only positive qualities - there are disadvantages in everything. On the forms, I had to look for negative reviews of people living in such structures.

1. Many chemical constituents in the material

Written by a user who recently built a house from SIP panels. The review is controversial, although we attached it to the negative ones, but these are just human fears.

The house was built quickly, it seems to me that this is a matchbox, and soaked in all sorts of formaldehydes and resins. The walls are not thick, the house is not cold, but there is no trust. There are no mice, but I believe that this is due to the fact that they do not eat chemistry. For ventilation, I invested in an expensive project, I'm afraid to use it - all of a sudden it will take out all the heat from the house. I want to sell the house and start building a brick one.

2. No demand for SIP panel

A small team involved in the construction and sale of houses left a review that did not characterize the technical performance. But it is worth mentioning, this is an occasion to make sure that new technologies in the construction of SIP panels are accepted by the inhabitants of our country with great concern.

We are engaged in the implementation of finished objects. We buy land, build a house, and sell it. SIP panels - let down a lot. The house was built quickly, it turned out to be a beautiful building, reliable - but there are no customers. Who does not look, everyone thinks that this is a waste of money, the house will fall apart in 10 years. Now put up for sale at cost, recapture what we spent.

3. Poor soundproofing

Of course, the issue of the cost of a property is relevant in our country, there are users who put forward specific claims to houses from SIP panels.

The house was built for two families, they wanted to save money. Naturally, the material was inexpensive, but the isolation from the noise of the neighbors is almost zero. As long as something is happening in the house, the TV is on, music is playing, it's normal. But in the evening you turn off everything, and the neighbor's children start running around, then being in the house is almost unbearable, there is a clatter, that at least run away. Of course, they decided by making additional soundproofing, but this is also a plus for money.

4. Application of polyurethane foam

This is rather a question that remained unanswered on the forum because people who have been living in a house from SIP panels for quite a long time are satisfied with everything.

The seams are sealed with mounting foam. The manufacturer of the material claims that the foam has been serving for no more than twenty years, and it is not clear how things will continue. Take everything apart and seal it all over again? How did the tenants who lived in the house for a long time act?

As you can see, there are, of course, disadvantages, but all are subjective, so:

- application chemical compositions that affect the microclimate in the room. Indeed, in the production of panels, resin is used to glue chips, but people living in such houses talk about a good and comfortable microclimate;

- low sound insulation, which, in principle, will not affect a single-family house. Not an indicator - a house built of aerated concrete without the use of additional noise insulation has the same properties;

- additional ventilation is required. As in any building from another material;

- low demand for material in the construction market. People rarely embrace new technologies with a bang. In our understanding - good house must be made of wood, concrete, brick or timber, all other materials cause fear and mistrust.

It is worth noting that any material can have negative aspects, and all the disadvantages of the above can be attributed to other materials and criticized.

If in fact, then SIP panels have much more positive characteristics than disadvantages. People are increasingly resorting to this construction technology, because it is a real opportunity to acquire their own housing at a normal cost.

Conclusion

Despite the inconsistency of reviews, it is worth noting that SIP panels are a promising, inexpensive material that allows you to quickly build a residential building. In our country, the problem of housing is acute, but by applying this technology, a family with a small budget can afford such a structure.

Despite the distrust of the SIP panels of our citizens, it is worth noting that in Europe cottages are being built, the height of which is more than three floors, and they show themselves perfectly in operation.

The main criterion, when deciding to build a building for permanent residence using this technology, will be the right choice of contractor. Indeed, in most cases, the reliability of the building depends on who built the building. Only thanks to the qualified actions of the builders, you can not be disappointed in the construction.

There are four main advantages of sip panels in comparison with other technologies.

First- high energy efficiency. Due to the low thermal conductivity of expanded polystyrene, as well as the minimum number of joints and their good sealing, we get a house that retains heat inside for a long time - about 8 times longer than in brick or concrete structures. In winter, a cold house can be warmed up in two to three hours, and when the heating is turned off, the temperature will drop by only one degree per day.

Second- ease of construction. A standard sip panel measuring two and a half meters by a twenty-five meter with a thickness of 174 mm weighs only 50 kg. This allows loading and unloading operations, installation on the second tier without the use of special construction equipment. A team of only 3 people can lift the panel. In addition, the pressure on the foundation from the weight of the structures is minimal. This makes it possible to install houses on complex loamy soils on screw piles and not be afraid of frosty heaving of soils in winter. A light foundation, in turn, is much cheaper, and this is a significant part of the construction budget.

Third The advantage of sip panels is quick installation. A house with an area of 150 m 2, or rather its thermal circuit, is assembled on average in 2-3 weeks. This speed is achieved due to the ease of assembly and the enlarged structures of the sip panels themselves. At the same time, the house is already ready for exterior and interior decoration - there is no need to wait a year for the building to completely shrink.

Fourth- low cost of the house and minimal costs in the process of its operation. The sip panel technology is the most economical of all existing ones. Savings are manifested both in the purchase of the necessary building materials, due to their low cost, and at the installation stage, since light structures are mounted with simple nodal solutions. And the high energy efficiency of the house will make it possible to recoup the cost of construction in ten years only on heating.

Also, the advantages of sip panels include the ability to carry out construction and installation work in the winter. There are no “wet” processes during construction, so low temperatures are not a hindrance. Work with the foundation can also be done in the cold season, since a light house made of sip panels can even be placed on screw piles.

Cons of sip panels

The disadvantages of sip panels are traditionally considered a fire hazard. But let's see.

Like any wooden structure, vulture without finishing has a third degree of fire resistance. But there is much less material that supports combustion in a Canadian house than in an ordinary wooden one. In addition, self-extinguishing polystyrene foam is used in modern vultures, which ignites at a higher (almost 2 times) temperature than wood. You know that any houses are on fire. If a brick structure burns down, the foundation and walls will most likely remain, but will be subject to demolition due to a loss of strength by 60-70%. So when we talk about fire safety private house, it is better to discuss sufficient time for the evacuation of people before the destruction of power structures. In a house made of sip panels, the floor joists are destroyed first of all, and not the walls. Therefore, they must be treated with fire protection and protected with non-combustible materials. It is possible to increase the fire resistance of OSB-3 boards by painting with fire-retardant paints. But it is better to additionally finish with drywall or gypsum board without the use of guide profiles. That is, so that there is no air between the surfaces. Such a wall will withstand 45 minutes of exposure to open fire! Of course, a set of fire-fighting measures is necessary both in a wooden and in any other building. Fortunately, today there are fire alarms and fire extinguishing systems.

Do mice chew on styrofoam?

Styrofoam is inedible for rodents, that is nutritional value does not represent for them. Rodents are drawn to warmth, so they can crawl under the panels to warm themselves. Or make moves in them. Therefore, expanded polystyrene, like any insulation, must be protected. OSB-plates in sip-panels tightly close the foam. If you want to take additional measures, you can lay a metal mesh under the exterior wall decoration, but this does not make much sense. In any case, protect low-rise building rodents will still have to. Effective preventive measures are known.

Canadian construction technology has gained popularity in many parts of the world. First of all, the construction of SIP panels is built very quickly. In the conditions of the north, SIP panels are an excellent option, since they have high rates heat saving. For the production of this building material OSB board and thermal insulation material is used. Most often, expanded polystyrene is used for this purpose. Before starting construction, it is important to know all the pros and cons of houses from SIP panels.

This building material is distinguished by simplicity of design and affordable price. With all this, they are favorably distinguished by the advantages:

This building material is distinguished by simplicity of design and affordable price. With all this, they are favorably distinguished by the advantages:

- high thermal insulation;

- strength;

- light weight;

- durability;

- affordable price.

Characteristics

Weighing all the pros and cons, it is worth considering also the main specifications plates. According to European standards, such a plate can have the following dimensions:

- width - 1.25 and 1.2 m;

- length - 2.5 and 2.8 m (in some cases 3 and 6 m).

American standards are measured in inches. On the territory of Russia, such sizes are extremely rare. The most popular is the standard 2.44 and 1.22 m. The thickness of the material may be different. To a greater extent, it depends on the thermal insulation material. The insulation can be 100, 150 or 200 mm thick. For the manufacture of SIP panels, OSB sheets with a thickness of 9 or 12 mm are used. These are the main advantages of building material. In addition to this, you also need to familiarize yourself with the main disadvantages.

Advantages

In order to start building a house, you need to make a foundation. Using brick or concrete blocks, you need to make a monolithic base with a sufficiently large depth. Using SIP panels, the foundation can be made less bulky. This is due to the fact that the walls will eventually exert little load. On average, the weight of one panel is 60 kg.

Pluses consist also in high fire resistance. During testing, it was found that the material is able to contain fire for one hour. This makes the material of the third degree of fire resistance. They also have such a positive quality as self-extinguishing. This is due to the fact that the composition includes antiperine. The material is non-toxic and does not emit any toxic substances when ignited. OSB and expanded polystyrene are absolutely safe for human health. Therefore, they can be safely used for the construction of temporary and residential structures.

- Durability is one of the advantages of SIP panels, against which nothing can be said. For construction, this indicator is very important. On the walls in the future it will be possible to hang shelves, brackets and other heavy pieces of furniture.

- Stability can be provided by adding a stiffening frame, which is used as vertical and horizontal bars inside the structure.

- Rigidity is achieved due to the fact that the gluing of all layers is carried out with a special adhesive under pressure of the press. Durability is an undeniable advantage. On average, SIP panels are able to serve for more than 50 years, while retaining all their advantages, resisting various influences.

- The small thickness of the panels is important during construction. The thickness is three times thinner than masonry, while all the heat-saving characteristics meet the standards.

- For interior and exterior decoration, you can use a variety of materials. Thanks to a perfectly flat surface, there is no need to carry out preparatory work.

Flaws

Despite the fact that Canadian technology houses have a huge number of advantages, before starting construction in without fail It's worth looking into the pros and cons. Knowing all the shortcomings, solutions can be found against them. This will extend the life of the house and eliminate all the risks of living in it.

Despite the fact that Canadian technology houses have a huge number of advantages, before starting construction in without fail It's worth looking into the pros and cons. Knowing all the shortcomings, solutions can be found against them. This will extend the life of the house and eliminate all the risks of living in it.

The reliability and strength of the structure as a whole depends directly on how accurately the construction technology is observed. In addition, it is worth exploring all the shortcomings of houses from SIP panels.

- Flammability. Compared to wood, panels are not as susceptible to fire and are more resistant to fire. But, despite this, during construction it is important to do the wiring correctly, pay special attention to the locations of sockets and switches. As an additional protection, you can use special means - anti-feathers. Also, to increase fire resistance, non-combustible building materials should be used as sheathing.

- In some cases, the thermal insulation material can be damaged by rodents. Therefore, it is important to control all joints so that there are no cracks and gaps through which pests can crawl. Such shortcomings are extremely rare.

In order for the building to turn out to be as strong and reliable as possible, it is worth using the recommendations of specialists regarding construction. Knowing all the pros and cons, you can even do the work yourself.

- The first thing is to find quality products. Only in this case, the panels will withstand the entire expected load. Unscrupulous manufacturers can use low-quality adhesive, as a result, the panels can simply stick out. You need to choose a supplier responsibly, it is best to use the recommendations of relatives and friends who have already made purchases.

- As a base, you can use practical screw piles or a shallow tape monolith. This makes it possible to significantly save money on all construction.

- A special technology for the production of panels provides them with maximum rigidity. This makes it possible to build a house at any time of the year, even at low temperatures. The structure after construction does not shrink and is not subject to seasonal heaving of soils.

4. It is important to make a quality frame that will hold all the walls. For exterior walls, thicker versions of SIP panels should be used. For interior partitions, a thinner option is suitable. It is also necessary to individually select the option for arranging the gable under the roof. - All work should be carried out in stages and in compliance with all technologies and standards.

Knowing all the advantages, you can as a result get a reliable structure of a temporary nature or permanent residence. Pros and cons fully characterize the material and favorably distinguish it from other options

Sandwich panels are large-sized structures. They are three-layer, inside of them there is a heat-insulating layer. The surface of the panel does not need processing. The technology for the production of houses from sandwich panels has long been used in many foreign countries. In Russia, houses made of SIP panels are sometimes called Canadian ones. This construction technology is considered a type of frame.

Pros and cons of houses from sip panels: what is a sandwich panel, their advantages and disadvantages

What is a sandwich panel?

The house is assembled from panels that were produced in the factory or independently at home. Properly produced SIP panels are quite durable. Of these, you can even build structures without a frame. Such panels are able to withstand not only the structure of the house, but also the impact of external factors, such as wind.

The house is assembled from panels that were produced in the factory or independently at home. Properly produced SIP panels are quite durable. Of these, you can even build structures without a frame. Such panels are able to withstand not only the structure of the house, but also the impact of external factors, such as wind.

Advantages of houses from SIP panels

- Environmental friendliness. The technological basis for the construction of houses from SIP panels is the use of 3 materials: pressed boards, expanded polystyrene, dry calibrated wood frame. All these materials do not emit hazardous substances into the atmosphere, so they are harmless to humans. Food utensils are also made from expanded polystyrene.

- Reliability. Houses built using this technology have great strength, so they are built even in earthquake-prone areas. A large number of such houses are being built in Japan. The sandwich panel can withstand enormous loads. In Canada and America, five-story houses are being built using this technology.

- Durability. Some argue that such houses can stand up to 40 years. It is true, you can even say that the service life of these houses is much longer. Service life up to overhaul is 50 years old.

- Fast erection. Due to the fact that large-format panels are used, a high speed of installation can be achieved. A team of 3 people can build such a house in 3 weeks. As a rule, the construction period does not exceed 2 months. At the same time, the construction includes interior and exterior decoration, cladding, electrical work, etc. The walls of SIP panels are very smooth. This property is not lost over time. So these houses look very beautiful. In addition, the smooth surface of the walls makes the interior and exterior decoration lower. You can save time and money. The design of such a house does not shrink. So you can start decorating the house immediately after installing the main structure. You won't have to wait.

- Availability. The cost of building houses using this technology is much lower than building using other technologies. The thickness of the walls of SIP panels is small. The design is quite light, so there is no need to build a solid foundation. There is also no need to use heavy equipment for construction. The cost of building such a house is very low.

- SIPs save heat and energy. frame houses perfectly retain heat. Moreover, this property is achieved at low cost. Bright rooms are another advantage of frame houses. After all, the thickness of the outer walls is relatively small, it becomes possible to achieve such an effect. You can easily increase the lighting due to the increase in window structures. The Canadian house warms up quite quickly. This may please those who like to quickly turn off the heating in winter.

- Soundproof SIP. Despite the fact that the thickness of the walls of such a house is small, they do not conduct unnecessary noise. Insulation can also act as sound insulation.

- Design freedom. The load-bearing walls in a house can determine the floor plan. In such a house, the layout is almost free.

Disadvantages of houses from SIP panels

- Flammability. Sandwich panels are poorly protected from fire. Compared to wood, they have better protection, but it is insufficient.

- Rodents. This disadvantage is not so significant, because rodents often damage the insulation. They do not touch the sandwich panel itself.

As you can see, the advantages of houses made of SIP panels are much greater than the disadvantages. This is another reason to make a choice in favor of building houses using this technology. You won't spend a lot of money, but you will get

As you can see, the advantages of houses made of SIP panels are much greater than the disadvantages. This is another reason to make a choice in favor of building houses using this technology. You won't spend a lot of money, but you will get